- Have a Question? 1.800.832.7111

- Contact Us

- 0

As a global leader in resilient vinyl flooring, Lonseal® has supplied the aviation industry with high-performance aircraft flooring solutions for more than 52 years. Our reputation is built on engineering expertise, lightweight innovation, and long-term durability trusted by aircraft designers and manufacturers worldwide.

Lonseal® aircraft flooring is engineered with a featherweight construction that is up to 30% lighter than standard Non-Textile Flooring (NTF) aircraft flooring products, delivering a superior strength-to-weight ratio. This lightweight advantage helps reduce overall aircraft weight while maintaining exceptional durability, making Lonseal a preferred specification for aircraft OEMs, interior designers, and airplane manufacturers. Our flooring systems are designed to meet the evolving performance, safety, and efficiency demands of today’s aviation industry.

Lonseal® serves a broad range of aviation clients, including commercial airlines, aircraft manufacturers, and MRO facilities. Our aircraft flooring products are installed in entrances, galleys, flight decks, and lavatories across nearly every aircraft type. Select Lonseal products meet Boeing and COMAC material specifications, and all products comply with FAA safety standards.

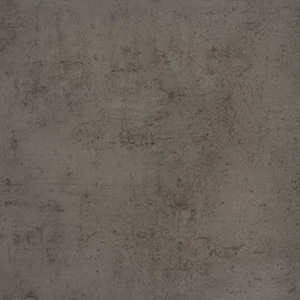

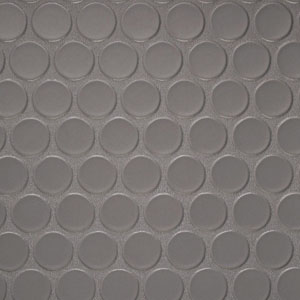

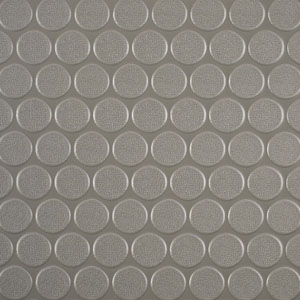

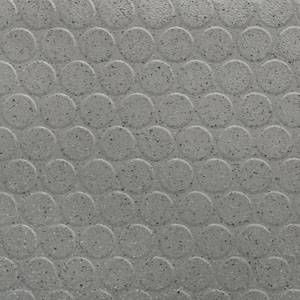

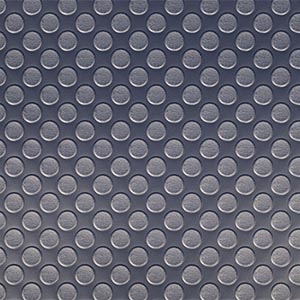

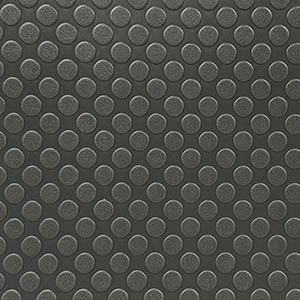

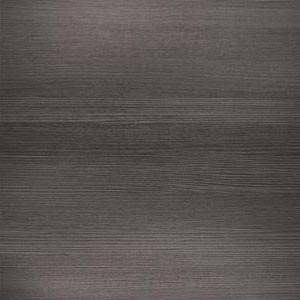

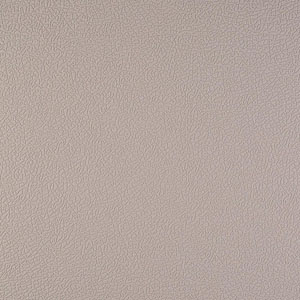

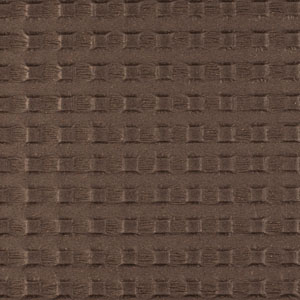

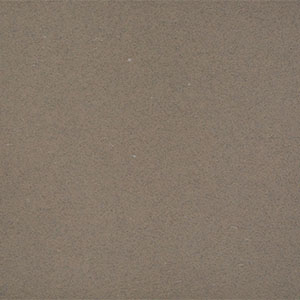

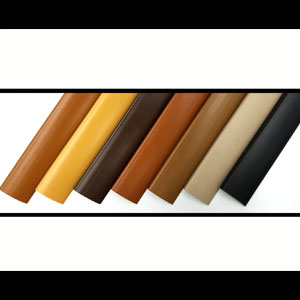

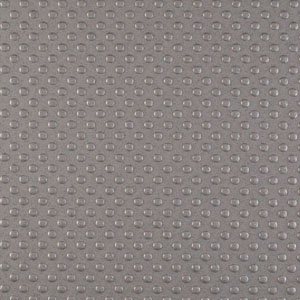

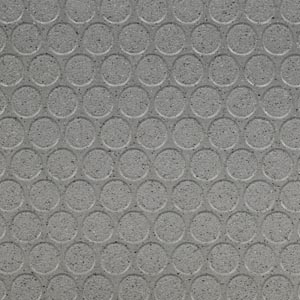

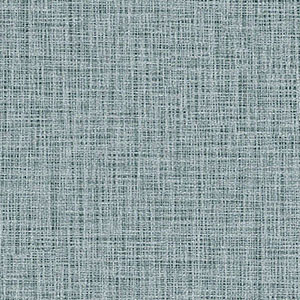

From wide-body passenger aircraft and cargo planes to charter helicopters and private jets, Lonseal® aircraft flooring offers an extensive selection of durable surface designs. Our wide-width sheet vinyl flooring minimizes seams and makes seam welding virtually unnecessary in smaller areas. Proven multi-layer construction technology preserves color and pattern integrity under heavy traffic and long-term use, ensuring reliable performance in demanding aviation environments.

Lonseal® aircraft flooring products also comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), the European Union regulation governing chemical substance safety. As REACH continues to set global manufacturing standards, Lonseal remains at the forefront of sustainable, compliant aviation flooring solutions.

Lonseal Aircraft flooring attributes include:

- REACH compliant formulation

- Featherweight feature

- Some of the lowest VOC properties in the market

- Custom coloring and patterning available

- 72 in (1.8 m) and 96 in. (2.4 m) wide rolls available

- World-wide product stock for timely order shipment

- Meets FAR 25.853 and FAR 25.793

Related Products